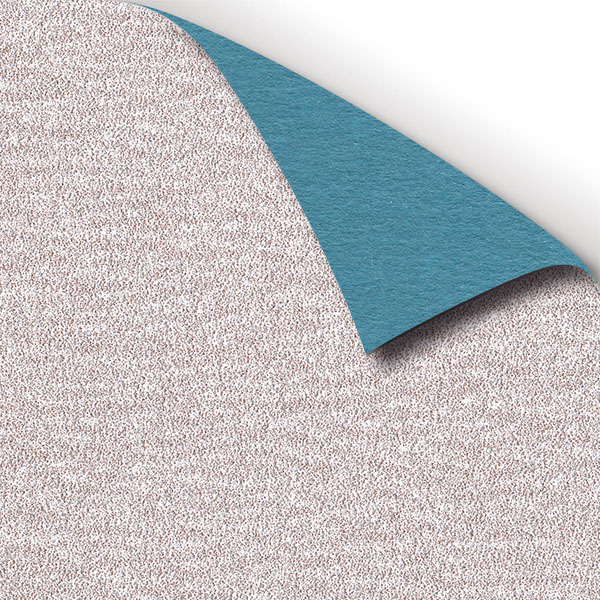

Special processed backing keeps its shape, makes it moisture resistant and is unaffected by changes in temperature and humidity. Antistatic construction gives low gathering dust on belt and workpiece.

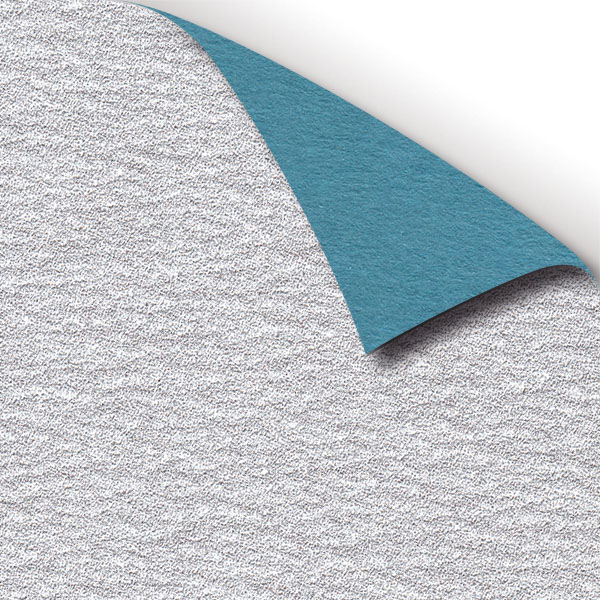

Superior surface quality when sanding on industrial paint systems for removing paintwork defects. Dust-free process: antistatic construction gives low dust formation on belt, workpiece and machinery.

Extremely adaptable to contours which can polishing smooth, even surfaces, even on curved workpieces. Premium silicon carbide can be used on oiled surfaces, and polishing preparation for high-gloss surfaces.

1. Our products are much more quiet than the other products when you use it.

2. With poly-cotton backing for fast stock removal and cooler grinding on stainless steel.

3. Are less likely to gouge, undercut or otherwise ruin the workpiece.

4. Aggressive stock removal rate and long lifetime.

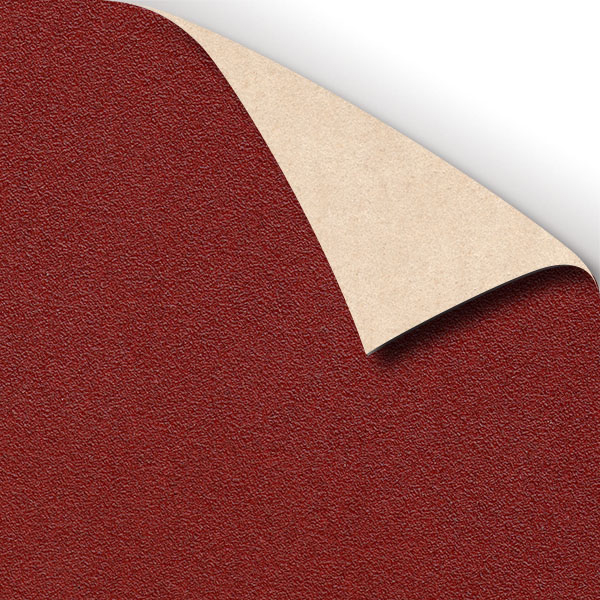

Heated Aluminum Oxide provides better cost-effective for general portable machine sanding purpose. Excellent heat dispersion Anti-clogging layer keep cooling during sanding metal surface.

Iridium plated aluminum oxide grain improves performance (better sharpness) and cuting rate during sanding wood and soft metal workpieces. Unique Fiber-reinforced C-weight backing paper improves comfortable (tear-resistance)and flexible.

Awt-High Latex content Paper backing means highly flexible and comfortable for manual operation. Silicon Carbide grain has a shorter life than aluminum oxide, it produces a superior finish.

Mixed with Zirconium grain at coarse grits which can reach high stock removal rate. Polyester Film backing could be much more durable than paper backing.

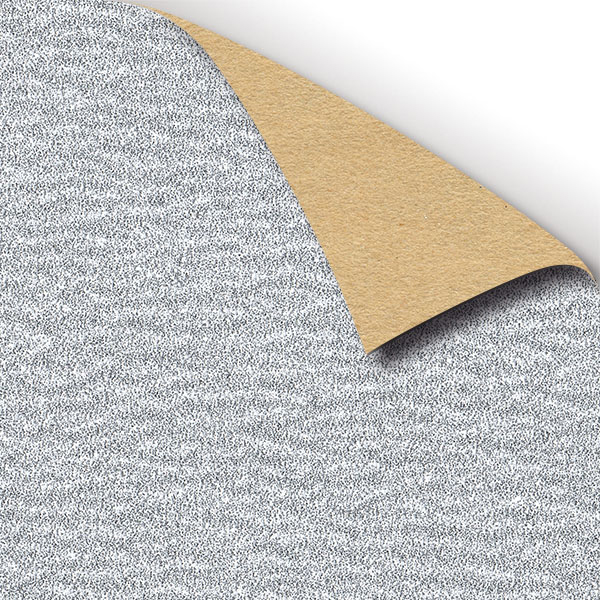

This durable sanding material is well suited for high speed sanding in automitive painting and refinishing. Gold features open and special stearate coatings designed to prevent clogging which helps achieve an optimal sanding result.

Better cost-effective for general purpose. High stock removal rate thanks to close coated grits.

Suzhou Star Abrasive Products Co., Ltd.It has three manufacturing bases in Hangzhou, Shanghai and Yancheng. The bases and one trading company built a complete supply chain system. It have six advanced full automatic production lines, twelve convertion lines and well equipmented R&D center. The system pay more attention to the mediu...

Address of Converting Factory: Building A, NO.56 Zhongjie Road,Qiandeng Town, Kunshan City, Jiangsu province, China.

Tel: +86 512 57468266

Fax: +86 512 57468266

E-mail: star@star-abrasives.com